Hydraulic cylinders convert the under pressure flow of fluid to the linear movement of piston and are classified in two categories of single-acting and double-acting. In single-acting ones, reversion is done by spring or weight force. But in double-acting reversion is done by under pressure hydraulic fluid. There are some important parameters in choosing a cylinder:

- Maximum pressure of system

- Diameter of piston and rod

- Force of cylinder

- Maximum force of cylinder

- Stroke of cylinder

- Maximum speed of cylinder

- Installation of cylinder

- Existence of damper

- Usage of cylinder

The common problems related to hydraulic cylinders are as follow:

- Non-axial loading

- Incorrect installation

- Buckling in rod

- Mistakes in calculation

- Impact loads

- Leakages

- Increases in pressure

- Incorrect movements of piston

- Calculation of force and speed of cylinder

In order to determine the force, first the pressure should be calculated. The 160bar, is a common pressure in industries. With considering the force and the pressure, the required are of piston is calculated from the below formula :

F (kgf)=P(bar)×A(cm2 )

The speed of cylinder is related to the entrance flow rate. Over 0.1 m/s and under 0.01 m/s speed needs special requirements in system. The cylinder speed is calculated from below :

V(m/sec)=Q(lit/sec)/6XA(cm2 )

Cylinders are classified in two categories :

- single-acting

- double-acting

- Single-acting cylinders

In single-acting cylinders, just the piston side is filled by oil, so that the cylinder can be moved in just one direction.

This cylinder is used when just one directional movement is needed. In long strokes, we use single-acting telescopic cylinders.

- Double-acting cylinders

in double-acting cylinder, both side of piston can be under pressure.

- Allowable pressure

The allowable pressure, is the pressure that can be applied in the cylinder during loading without any harm to it. The standard pressure of cylinders is written in the following table:

![]()

The gray ones in table, are common pressures used in industries. It should be considered that the test pressure is more than working pressure and cylinder should be designed for testing pressure. The test pressures for the each working pressure is :

- Diameter of piston and rod

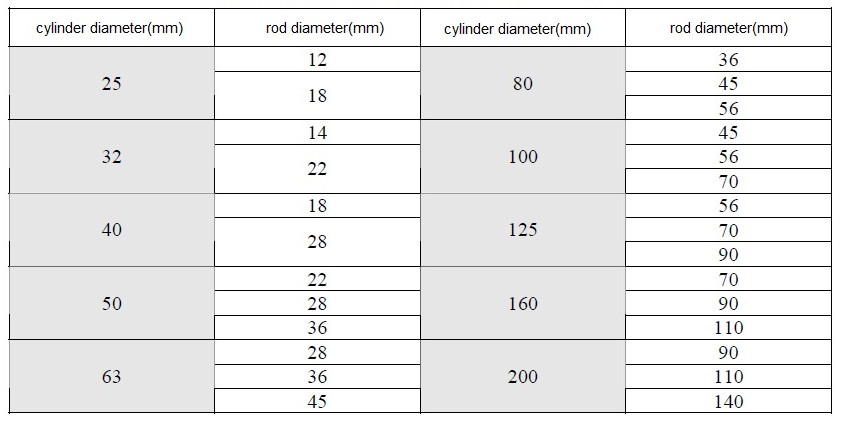

The amount of the generated force by the cylinder is related to pressure and area of its piston. It should be considered that area of rod is different at the both side of the double-acting cylinders. The following table includes Standard size of the diameter of the cylinder and rod :

Even other diameter range is used in different industries, and the above table, is common ones.

- Stroke

The stroke(witch is usually reported in centimeters) reports the movement range of cylinder. The most struggling point in designing a cylinder, is buckling. It means with having a certain diameter of piston and diameter of rod and pressure, we are allowed to choose special range of stroke.