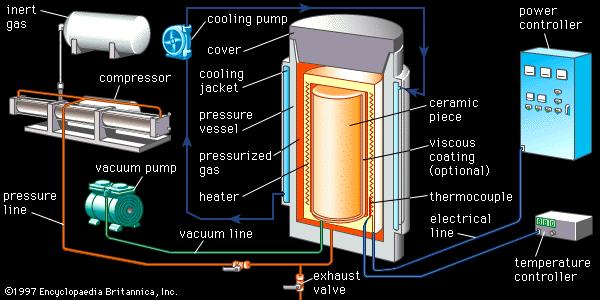

In general, hot isostatic press (HIP) components are divided into thermocouple, pressure increasing system, heating elements, pressure vessel and the furnace.

In pressure vessels, that commonly use argon gas, the compression process takes place. Generally inert gases are used to prevent chemical reactions inside the vessel. The vessel is heated and it’s internal pressure will be increased. Most of the systems use gas pumping in order to achieve the desired pressure level. The products are under pressure from all directions, so this process is called isostatic. The vessel’s wall is forged by steel rings or is covered by fatigue-resistant steel wires.

While hot isostatic pressing process, the materials are compressed to each other at 1450 centigrade and the pressure rises up to 200 Mpa. The internal components of pressure vessel should be resistant against the fast changes of temperature. So that in production of furnace, we should use materials with high heat capacity like tungsten and molybdenum. For consolidating the molybdenum structure we can add titanium and zirconium.

Electricity flows through heating elements and heat is produced. Used materials in production of these elements are mostly from tungsten, molybdenum, tantalum, niobium and their alloys.