The use of high hydrostatic pressure as a method to preserve food products has gained commercial importance in recent years. High Pressure Processing (HPP) is a pasteurization method that uses pressure rather than the traditional method of heat to kill microorganisms in foods. This process, like thermal processing, helps to both extend the shelf life of foods by killing spoilage organisms, including yeasts and lactic acid bacteria, and improve the safety of foods by killing vegetative pathogenic microorganisms like Escherichia coli O157:H7, Salmonella, and Listeria monocytogenes. However, unlike thermal processing, HPP is less destructive to key food quality components such as vitamins, flavor compounds, and pigments, which helps products processed in this manner keep qualities associated with fresh, unprocessed foods. Thus, HPP not only improves the safety of foods, but also extends the shelf life of foods while maintaining food attributes normally associated with “minimally processed” foods.

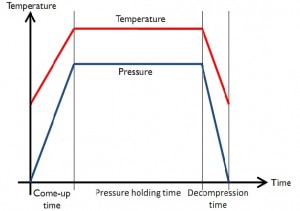

HPP of foods involves a standard processing profile. Pressure is increased at a certain rate until the target pressure is reached, the target pressure is held for a specific amount of time, and then pressure is released at a specific rate. Typical pressures applied to foods range from 300–800 MPa (43,500–116,000 psi). Heat may also be applied, however, the majority of high pressure processes are conducted at refrigerated temperatures, relying mainly on pressure to process the food. It is important to note that some temperature increase does occur naturally during a typical HPP treatment due to adiabatic heating, which is dependent on the target pressure and food composition. While the temperature increase of water is approximately 3°C per 100 MPa, this can be significantly higher for more compressible food ingredients like fats, resulting in a greater temperature increase during pressurization for foods with higher fat content. A schematic representation of the pressure and temperature profile of a typical HPP treatment is provided in figure below.

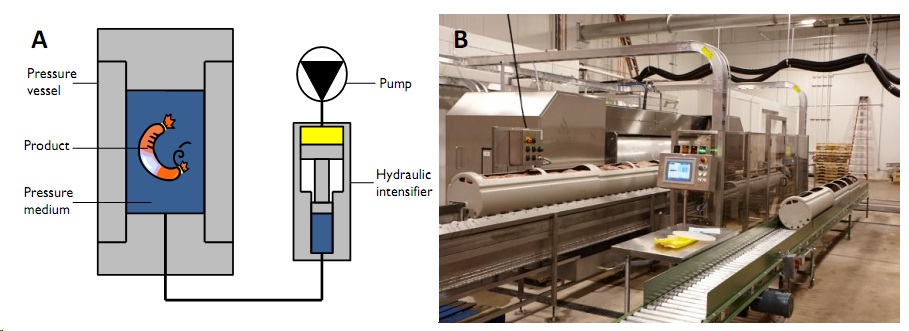

A typical HPP batch system consists of four key components; the pressure vessel, pressurization fluid, intensifier, and pump. Alternatively, the pressure vessel can additionally be designed as a pressure intensifier. The pressure vessel is built to withstand a certain amount of pressure and temperature, and contains the packaged food product and pressurization fluid. Pressure vessel sizes are defined by the volume of fluid that the vessel can hold, and can range from several milliliters for research units to several hundred liters for commercial units. The pressurization fluid is typically water, and is added to the pressure vessel to eliminate air pockets between the packages of food. Once the pressurization fluid is added, the hydraulic pressure intensifier and pump are used to increase the pressure inside the cell and the pressure is transmitted through the pressurization fluid through the packaging material to the food itself. As the pressure is applied uniformly over the whole surface of the food product, the shape of the food is maintained.

A typical HPP batch system consists of four key components; the pressure vessel, pressurization fluid, intensifier, and pump. Alternatively, the pressure vessel can additionally be designed as a pressure intensifier. The pressure vessel is built to withstand a certain amount of pressure and temperature, and contains the packaged food product and pressurization fluid. Pressure vessel sizes are defined by the volume of fluid that the vessel can hold, and can range from several milliliters for research units to several hundred liters for commercial units. The pressurization fluid is typically water, and is added to the pressure vessel to eliminate air pockets between the packages of food. Once the pressurization fluid is added, the hydraulic pressure intensifier and pump are used to increase the pressure inside the cell and the pressure is transmitted through the pressurization fluid through the packaging material to the food itself. As the pressure is applied uniformly over the whole surface of the food product, the shape of the food is maintained.

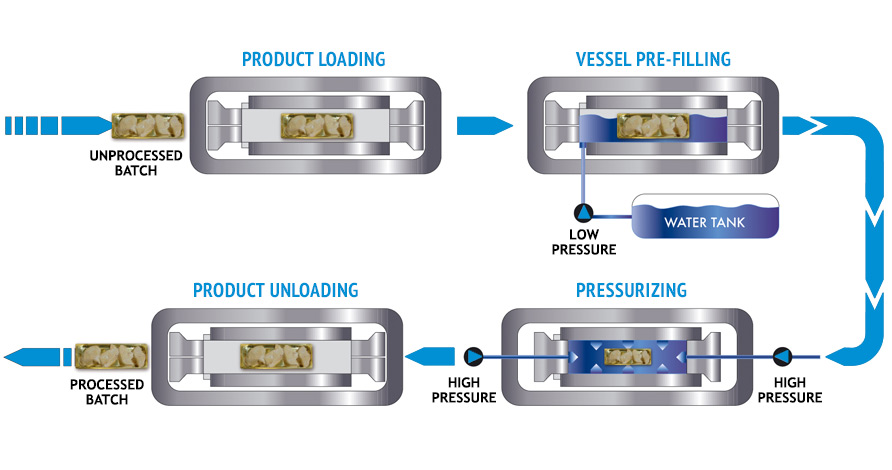

Below figure schematically shows the HPP process.

Below figure schematically shows the HPP process.

In order to achieve the best pressure transmission within the food product, the ideal food for HPP processing has no gas inclusions, no head space in the package, and high moisture content. Additionally, the type of material used to package the food product also has to be suitable. The packaging material has to be flexible enough to transmit the pressure without structural damage. Due to pressurization, the food is compressed and the package has to allow this reversible deformation. Rigid materials like metal and glass are not recommended, as they will not be able to withstand the HPP treatment. Vacuum packed products in flexible packages appear ideal for HPP, particularly if the package can be compressed by about 15 percent without suffering structural damage and it is able to return to its original shape upon pressure release. Currently, flexible packs, jars, trays and bottles are used as HPP packaging.

In order to achieve the best pressure transmission within the food product, the ideal food for HPP processing has no gas inclusions, no head space in the package, and high moisture content. Additionally, the type of material used to package the food product also has to be suitable. The packaging material has to be flexible enough to transmit the pressure without structural damage. Due to pressurization, the food is compressed and the package has to allow this reversible deformation. Rigid materials like metal and glass are not recommended, as they will not be able to withstand the HPP treatment. Vacuum packed products in flexible packages appear ideal for HPP, particularly if the package can be compressed by about 15 percent without suffering structural damage and it is able to return to its original shape upon pressure release. Currently, flexible packs, jars, trays and bottles are used as HPP packaging.

Currently, commercially available HPP products for which HPP has been successfully validated as a kill step include the following:

- Vegetable & Fruits– Juices, salsa, dressing, guacamole

- Meat– Ready to eat meats and poultry

- Dairy– Milk, cheese, yogurt

- Seafood– Shellfish and fish products

- Drugs & Cosmetics

The main advantages of this technology can be summarized as:

- The fresh taste and texture of products such as fruit juices, shellfish, cooked meats, dips, sauces, and guacamole is retained.

- Microbiological safety and shelf life are increased by inactivation of pathogens and spoilage organisms and also some enzymes.

- Innovative foods can be produced, such as gelled products and modification of the properties of existing foods, for example, milk with improved foaming properties.

- There are savings in labor compared with more traditional techniques, for example, self-shucking oysters.

- Energy consumption is low

- There is minimal heat input, thus retaining fresh-like quality in many foods.

- There is minimal effulent.

- It leads to uniform isostatic pressure and adiabatic temperature distribution

- There is no additives.